Brand Name: HTEG

Model Number: Customization

Place of Origin: Shandong, China (Mainland)

China Supplier Boiler Spiral Finned Tubes Economizer with High Frequency Welding

The China supplier boiler spiral finned tubes economizer is a heat exchanger device that captures the "lost or waste heat" from the boiler's hot stack gas. The China supplier boiler spiral finned tubes economizer typically transfers this waste heat to the boiler's feed-water or return water circuit, but it can also be used to heat domestic water or other process fluids.

Capturing this normally lost heat reduces the overall fuel requirements for the boiler. Less fuel equates to money saved as well as fewer emissions - since the boiler now operates at a higher efficiency. This is possible because the boiler feed-water or return water is pre-heated by the economizer therefore the boilers main heating circuit does not need to provide as much heat to produce a given output quantity of steam or hot water. Again fuel savings are the result. The China supplier boiler spiral finned tubes economizers improve a boiler's efficiency by extracting heat from the flue gases discharged.

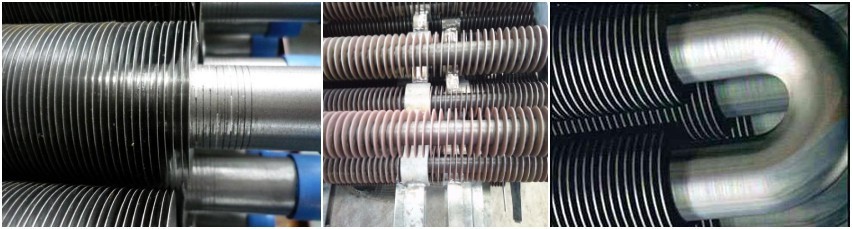

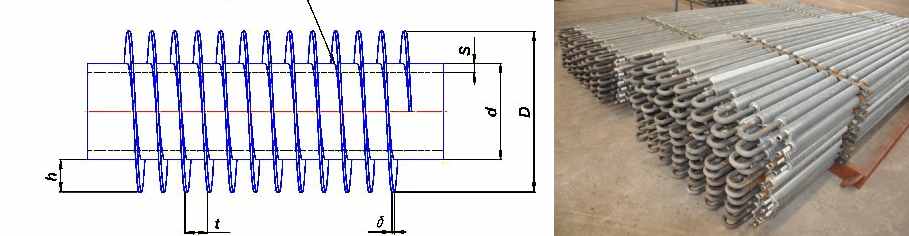

Process production

The China supplier boiler spiral finned tubes economizer is squeezing by high frequency welding method and the technology of steel strip according to certain structure automatically, continuous spiral welding outside the light tube wall, and then the other reserved part light tube bending, combination according to the requirement. As a result, the diameter and length under the same conditions, it has larger heat transfer area.

Material composition of boiler spiral finned tube economizer

It is made of spiral finned tubes, inlet header, outlet header, elbow and other supporting material.

The structural arrangement of boiler spiral finned tube economizer

Spiral finned tubes are in-line arrangement or staggered layout, water in the pipe.

Features of boiler spiral finned tube economizer

Due to the expanded heat transfer area, economizer tube row number decreases, thus reducing the possibility of the welding work and solder joint leakage, improve the safety and reliability of the pressure parts Heat transfer condition in the same conditions, its weight is lighter, about 70% of the light tube economizer, the materials about 45% of the light tube economizer;

1) Anti-corrosion

2) Anti-wear

3) Lower contact resistance

4) Higher Stability

5) Anti- dust

Other Products

Shandong Hengtao Energy Saving & Environment Protection Co., Ltd. established in 2003, which is specialized in designing, manufacturing, engineering, supplying of boilers, boiler components and boiler auxiliaries.

Our company has Grade A boiler manufacture qualification and Grade 2 pressure vessel manufacture qualification. Our main products are specialized in all kinds of boilers and boiler parts which included power station boiler, waste heat boiler, air preheater, membrane water wall and superheater. We are committed to creating the best solution provider for boiler integrated energy-saving technology transformation, and we will strive for it continually.

Our Workshop

Production Line Quality Control:

1. Strength calculation report with applied materials information;

2. 100%NDT(non-destructive inspection) report of steel plate, tube and welding rod;

3. 100%X-ray inspection report (welding seam): to ensure the quality of the entire boiler;

4. Hydraulic test report: ensure the standard working pressure and safety

Packing Details: We have standard seaworthy package and we also could try our best to package the product to meet your requirement.

Delivery Details: We have the most reliable transportation to make sure your goods arrived your destination as soon as possible.

Our Warm Service:

Every consumer has the chance to visit our workshop before placing the order. we will provide comfortable environment and completed product information for you to know our product deeply. Welcome your inquiry and sincerely hope we can cooperate with each other!

1) Certificate of conformity of quality management system certification

2) Environmental management system certificate

3) Occupational health and safety management system certificate

4) Installation, Alteration, Repair & Maintenance License of Special Equipment People's Republic of China

5) ASME Standard Qualification

Q1: Which port is closest to your location?

A: Qingdao Port is closest to our factory, about 1 hour driving distance to our place.

Q2: How long do you need the delivery time?

A: Generally, about 15 days, according to your product requirement.

Q3: What's advantage of your company?

A: We have exported our boilers, boiler parts and service to more than 50 countries./ We have specialized team work for you, and you will our feedback within 12 hours./ We also have Germany and Italian advanced manufacturing technology.